Storied items are key to corporate myth making; venerated implements can spark conversations that cause executives to be reflective and have more pride in the employer and more passion for their work.

Having obsolete industrial machinery on display, or primitive scientific apparatus preserved under glass commemorates decades of experience and symbolizes expertise wrought from empiric success. Such is the case at Lorpon Labels custom label printing in Toronto, Ontario where I found a Baltimore #9 Printer on display in their front office. This is a relic from the 1880s and its still hard at work today, but not as a printing press.

Having obsolete industrial machinery on display, or primitive scientific apparatus preserved under glass commemorates decades of experience and symbolizes expertise wrought from empiric success. Such is the case at Lorpon Labels custom label printing in Toronto, Ontario where I found a Baltimore #9 Printer on display in their front office. This is a relic from the 1880s and its still hard at work today, but not as a printing press. Lorpon Labels Displays a Museum Quality Printing Press that was a Custom Printing Solution in the Late 1800s

The Baltimore Printer #9 was a 'rail press', which is a modern term used to denote this type of printer where the action centers on a hand lever used to work the press. In their time these were called 'lever presses' and were the simplest printing machines available for purchase. They were deliberately small, cast-iron convenience presses capable of printing no more than a few short lines on a paper card.At the tail end of the American Industrial Revolution these items were being sold new for one or two dollars each. The printer was always sold as part of a home printers' package that consisted of the press, an ink roller and a couple cans of ink. There was also a pair of tweezers and at least two boxes of type—all in miniature. Blank cards were available everywhere stationary was sold.

Rail presses were produced until early in the twentieth century when they were succeeded by even lighter presses made of tin-plated steel and often quite gaudily decorated.

The new tin presses came complete with lightweight rubber type included in the package - these flimsy rigs were not strong enough to accommodate printers’ lead or steel type. The #9 Printer is an early version of more successful rail press designs that came later - this machine was made of cast iron and came with good solid steel type.

Spawned by America's rising demand for personal calling cards, the rail press was conceived as an alternative to professional printing. The marketing for other rail presses of the age appeals directly to businessmen for printing and numbering tickets, dating documents, and marking crates. By the 1870s these small card presses were made not only for shopkeepers, but for amateur printers and eventually even for children. The tin and rubber stamp models on the market at the beginning of the 20th century probably cost about fifty cents each and did a horrible job printing anything.

J. F. W. Dorman did NOT make Lorpon's antique; Dorman's firm produced a very popular range of hand lever presses that were closely copied by later manufacturers, notably Baumgarten & Co who also resided in Baltimore and also a man named Sigwalt who lived in Chicago. Dorman's Baltimoreans came first and were followed (copied) by Baumgarten's Baltimore No.9 and No.10 presses which are very similar with only minor differences in the casting and paint.

The Baltimore #9 Printer on display at Lorpon Labels was made by Baumgarten & Co who copied the design by J. F. W. Dorman, as per Briar Press Museum website. J. F. W. Dorman started in business in 1866 as a stencil cutter, becoming a supplier of rubber stamps and stationery materials. The company turned to making presses in the 1870’s.

The Dorman hand lever presses were very popular and were copied by several other companies, but the only company that went by the name of Baltimorean, was the original Dorman press. The Dorman factory was lost to the Great Baltimore Fire in 1904. The catastrophe didn't stop this American Captain of Industry however and his name reappears a few years later as the source of an entirely different type of collectible - porcelain license plates.

The Baltimore #9 Printer on display in the office foyer of Lorpon Labels was acquired by the Bob Pontarollo, CEO of the company in an antiques market in the USA for a couple hundred bucks, six years ago. That price was considered a bargain at the time. But what was the original catalog price? There doesn’t seem to be an online reference for the contemporary price of press that I can find today. If you know anything about it, please leave your knowledge in the comment section below.

Dorman’s hand 'Lever Presses' as they were sometimes called at the time were very popular, and were copied closely by several other manufacturers, notably John Sigwalt of Chicago (see his Chicago No.10, which lacks only the rippled ornamentation below its lever) and Baumgarten of Baltimore, who copied nearly every aspect of Dorman’s Baltimore line, including its name. Dorman’s presses go by the name ‘Baltimorean’ while Baumgarten’s use ‘Baltimore.’

The machine was operated by hand lever. This item measures 10 1/2" by 5" by 8" tall is composed primarily of iron but is mounted on a slab of wood.

Make no mistake this invention was not a giant breakthrough by any means except that it brought quality printing within reach of small businesses.

With this device, merchants could create their own printed cards and stock labels. A wealthy practitioner could own a Baltimore #9 Printer outright, while a less prosperous business owner may posses only a half or quarter share of such a press. In well connected neighbourhoods such a press may have been jointly owned by a dozen or more businesses and serve the printing needs of a small community.

There's an ink roller too or whatever this is also on display on the pedestal tray. The antique is 99% complete I believe; its only missing ink and paper. The name set in type in the chase is that of a woman and her address. Mrs Mary Johnson -- Sycamore Road. The rig could be easily refurbished and come to life again ...

With this device, merchants could create their own printed cards and stock labels. A wealthy practitioner could own a Baltimore #9 Printer outright, while a less prosperous business owner may posses only a half or quarter share of such a press. In well connected neighbourhoods such a press may have been jointly owned by a dozen or more businesses and serve the printing needs of a small community.

There's an ink roller too or whatever this is also on display on the pedestal tray. The antique is 99% complete I believe; its only missing ink and paper. The name set in type in the chase is that of a woman and her address. Mrs Mary Johnson -- Sycamore Road. The rig could be easily refurbished and come to life again ... Meanwhile Fortunes Were Being Made In The Newspaper Business

Friedrich Koenig’s cylinder press debuted in London England in 1812 and was famously employed by The Times of London in 1814. Printing newspapers was where history was happening in the 1800s. American flatbed cylinder machines, following European models, made their appearance in the 1820s and became the workhorses of big city newspaper and large job offices. Type was still supported on a flat bed which had to move back and forth, but the impression cylinder could turn continuously, speeding up the paper feeding operation. Typically, flatbed cylinder presses delivered a thousand sheets per hour, printed on one side only. Koenig’s press was a huge breakthrough, and its impact on society is hard to calculate. From its first appearance in the Napoleonic era, the cylinder press has played a dramatic role in the march of civilization... And in another product category altogether, the little Baltimore #9 Printer was decidedly, a step in the other direction. Lorpon's Baltimore #9 Printer probably dates from the 1890's, but it could have been made as late as 1910. We know it wasn't made before 1885 because its not a 'Baltimorean #9 Printer'. As noted earlier, the original Baltimoreans were made by J. F. W. Dorman Co., but later Baltimores were produced by Baumgarten & Co., Inc. The castings, decorations and nomenclature were so similar that nowadays, two hundred and thirty years later, only veteran collectors can tell them apart.

Lorpon's Baltimore #9 Printer probably dates from the 1890's, but it could have been made as late as 1910. We know it wasn't made before 1885 because its not a 'Baltimorean #9 Printer'. As noted earlier, the original Baltimoreans were made by J. F. W. Dorman Co., but later Baltimores were produced by Baumgarten & Co., Inc. The castings, decorations and nomenclature were so similar that nowadays, two hundred and thirty years later, only veteran collectors can tell them apart. Without the accompanying text, could you spot the Baltimorean?

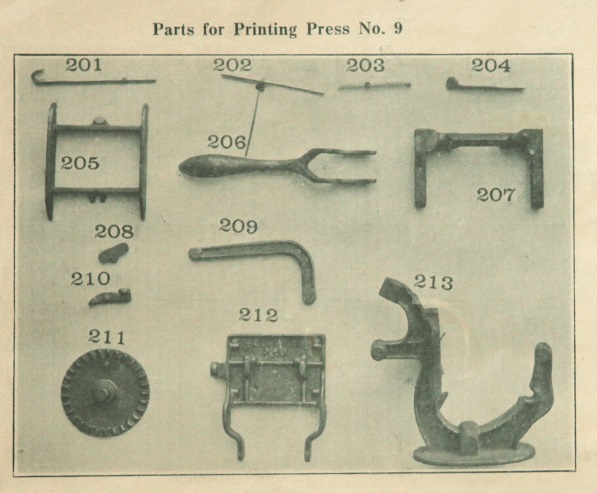

Without the accompanying text, could you spot the Baltimorean?This picture below is from a catalog in the 1890s - sadly, no prices

Index of Parts

Baltimore #9 Printer is indeed historic but not a trail blazer by itself.

Below is pg 736 of The Monumental, which outlines the life of John F Wesley Dorman. https://books.google.ca/books?id=8JUZTP4azZUC&printsec=frontcover#v=onepage&q&f=true

J. F. W Dorman was a pillar in the community , but not the only printer in Baltimore. Baumgarten & Co. produced a line of presses exactly parallel to Dorman’s, but used the name Baltimore instead of Baltimorean, and made minor changes in the castings.

J.F.W. Dorman was survived by Baumgarten & Co. Inc. The latter's descendants still run the original printing and rubber stamp making business. The photo below is the masthead of their website, Baumgarten.com

By making these hand operated presses for everyday people, both businessmen helped clear a path for the march of humanity. Today we can reflect back on how far we've come from inside the age of digital printing. Today we have full colour presses which are so good our paper currency has to be concocted from synthetic polymers and interspersed with translucent patches encasing magnetic stripes to deter counterfeiters.

No comments:

Post a Comment